H2SPlusTM Systems

Application – Iron Sponge Media H2S Removal System

MV’s H2SPlus™ Systems are in use treating biogas streams from landfills to anaerobic digesters at farms, wastewater treatment facilities and food & beverage processing operations. MV’s systems treat 30,000 cubic feet of biogas and landfill gas/min., every day and provide low cost solutions to H2S management in natural gas production and oil refining operations.

Anaerobic Digester Biogas Treatment:

Anaerobic digestion is a powerful process employed in various industries, notably on farms, in wastewater treatment plants, and within large waste and industrial facilities. This biological process not only aids in the effective management of organic waste but also produces biogas—a renewable energy source that can be harnessed for electricity, heat, or fuel. However, one of the significant challenges associated with biogas is the presence of hydrogen sulfide (H2S), a toxic gas that can pose health risks and damage engines and equipment. To address this issue, advanced treatment systems such as MV Technologies H2SPlus and SulfAx systems are increasingly being utilized to ensure safe and efficient biogas utilization.

The MV Technologies H2SPlus system employs a proprietary method that effectively removes H2S from biogas through a process of absorption and oxidation, resulting in clean, purified gas ready for beneficial end-use. This system is designed to operate seamlessly across various biogas processes, offering a flexible solution tailored for farms, wastewater treatment facilities, and large-scale waste management operations. In parallel, SulfAx systems provide another innovative approach for H2S treatment, utilizing biological and chemical methodologies to achieve remarkable reductions in sulfur content. Together, these systems contribute significantly to emissions control, transforming potentially harmful gases into a cleaner source of energy and supporting the sustainable practices essential for today’s environmental goals.

Landfill Gas Treatment:

Landfill gas (LFG) treatment has become an essential aspect of waste management, as it plays a critical role in reducing harmful emissions and enhancing the sustainability of landfill operations. At the forefront of this technology are the MV Technologies H2SPlus and SulfAx systems, which are specifically designed to address hydrogen sulfide (H2S) removal from landfill gas. These systems not only help ensure compliance with sulfur dioxide (SO2) emissions regulations but also facilitate the safe utilization of landfill gas as a clean energy source. By effectively treating LFG, these advanced systems enable landfill operators to convert this byproduct into valuable energy, minimizing environmental impact while maximizing resource recovery.

The applications of treated landfill gas are numerous and diverse. Once processed, treated gas can be used to fuel boilers and other industrial equipment, or it can be harnessed to power generator sets for electricity generation. Furthermore, the technology allows for the conversion of landfill gas into compressed natural gas (CNG), either for direct use or through connection to utility pipelines. This versatility not only mitigates the release of harmful gases into the atmosphere but also transforms landfill gas into a renewable energy source that can contribute to local energy grids. As landfill gas treatment systems like the H2SPlus and SulfAx become increasingly integrated into waste management practices, they represent a significant advancement in the effort to foster a more sustainable future.

Industrial Odor Control & Safety:

In the realm of industrial safety and environmental compliance, effective odor control is a crucial component, especially in hydrocarbon processing and petrochemical facilities. MV Technologies OdorFilter Systems have emerged as a leading solution for mitigating unpleasant and potentially hazardous odors, specifically targeting the removal of mercaptan and hydrogen sulfide. These systems play a vital role during key operational phases such as loading and offloading refined products, where emissions can pose significant health risks and regulatory challenges. By harnessing advanced filtration technology, OdorFilter Systems ensure that facilities maintain a safe and compliant workplace, mitigating the release of foul-smelling gases that can affect both worker safety and community relations.

The integration of MV Technologies’ OdorFilter Systems in various industrial environments highlights the commitment to air quality and safety. Many hydrocarbon processing facilities and petrochemical plants have adopted these systems to address odor complaints and ensure that emissions meet stringent environmental standards. The innovative design allows for efficient capture and neutralization of noxious compounds, including mercaptans, which are particularly notorious for their offensive smell. By deploying such effective odor control measures, facilities not only protect their workforce and surrounding communities but also enhance their overall operational integrity and reputation within the industry. Hence, MV Technologies continues to be a pivotal player in promoting sustainable industrial practices through their state-of-the-art odor management solutions.

CLICK to Downlod H2SPlus System for Biogas Brochure

CLICK to Download H2SPlus System for Landfill Gas Brochure

Design – Iron Sponge Media H2S Removal System

H2SPlus Systems are designed to remove low to moderate concentrations of hydrogen sulfide (H2S) and mercaptans from gas and air streams. In addition to the removal of sulfur-containing products, the system also will remove certain biodegradable, volatile, and semi-volatile hydrocarbon odors, together with amine odors. The basic H2SPlus System is a result of over ten years of in-field application and each component is sized to meet site-specific requirements. Systems can be easily configured to adjust to future changes (+/-) in process operating parameters. Key components of an H2SPlus system are:

- Media Vessel(s) – Fiberglass or stainless steel tanks sized to accommodate flow rate and maximize media life.

- MVNets™ and Fully Removable Lid – Provide dramatically easier removal of spent media when compared to other H2S removal systems.

- BioActive Media – Proprietary enhancement for removal up to 13lbs of H2S per cubic foot.

- Recirculation System – sized to maintain optimal moisture content of the media.

- Blower – sized according to system parameters.

- Spray Nozzle – positioned inside top of lid to keep media moist.

- Sump – used to recirculate minimal amount of water required for regeneration and maintains moisture.

- Monitoring and Control System – system monitoring of temperature, sump pump, and blower controls.

Fundamental Design Considerations

There are standard inputs required to properly size an MV H2SPlus™ system:

- Typical flow rates, both maximum and average

- Inlet concentration of H2S in the ‘raw’ gas stream

- Target (treated) H2S concentration level at the outlet of the scrubber

- Pressure (psi) – If the system is operated under pressure/vacuum.

- The source of the gas / industry

- The main reason for treating the gas

- The end-use for the gas

- Geographic location

The flow rate information determines the size and number of media tanks required. Geographic location determines if the tanks need to be insulated. The concentration determines the media consumption rate and informs other elements on the design of the system. The combination of the flow rate and the concentration yields the weight of H2S to be removed per unit time. You can estimate your annual H2S treatment requirements and media consumption cost here. We also need to know the intended use of the gas after it has been scrubbed. If it is intended for pipeline application or other uses that demand strict controls over concentrations, those will influence the system design as well. Media life between replacement cycles is calculated based on the H2S concentration, total flow rates, and specific system design. The final design selection is often a trade-off between system footprint limitations and target media change cycle time.

Technology- Iron Sponge Media H2S Removal System

The H2SPlus™ System approach to dry-scrubbing uses long-proven, low-cost iron oxide coated media (iron sponge) that MV Technologies has enriched with select bacteria and complemented with a system designed to extend media life and dramatically increase ease of system use. Iron sponge has been used to remove H2S from gas streams for more than 100 years and the media is comprised of wood chips coated with iron hydroxide.

H2SPlus Systems are currently in use throughout the U.S. treating a variety of gas streams to remove H2S & mercaptans and reduce SO2.

How it works

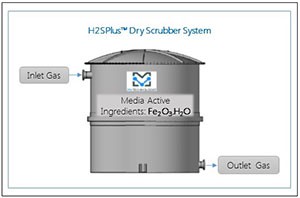

The H2SPlus System design is relatively simple in design yet elegantly efficient in effect. Landfill gas or biogas is flowed through the vessel inlet valve (top). The H2S present in the gas flows down through the media bed, neutralized via the reaction with MV’s bio-active media, and the ‘scrubbed / treated’ gas is then released through the outlet valve (bottom). H2SPlus™ Dry Scrubber System Reaction Process. There are two chemical reactions that take place in vessel:

The H2SPlus System design is relatively simple in design yet elegantly efficient in effect. Landfill gas or biogas is flowed through the vessel inlet valve (top). The H2S present in the gas flows down through the media bed, neutralized via the reaction with MV’s bio-active media, and the ‘scrubbed / treated’ gas is then released through the outlet valve (bottom). H2SPlus™ Dry Scrubber System Reaction Process. There are two chemical reactions that take place in vessel:

- In the primary reaction, H2S in the inlet gas stream reacts with the iron oxide (FexOy) in the media to form iron-sulfur compounds (FexOy), free sulfur and water.

- Oxygen present in the gas stream further reacts with the iron-sulfur compound liberating the sulfur and re-forming the iron oxide, making it available once again for the primary reaction.

These regeneration reactions require oxygen which may naturally be present in the gas stream or (a small amount) can be added by air injection at the scrubber. In the event that outlet gas conditions do not accommodate air addition, the secondary regenerative reactions can be performed “off-line” by taking the vessel out of active service. Additionally, H2SPlus systems:

- work anaerobically; with a very small amount of Oxygen to facilitate the reaction process.

- do not require high pressure in order to operate like some other systems. This results in lower horsepower/electrical requirement.

- economical sweet spot is between -2 to 8 psi. However, MV Technologies can design systems to operate at any pressure range. We would simple use our biologically-enhance granular media and adjust vessel size/type for psi 15 and above.

- operates with no need for a water treatment system or sewer line access.

- can be installed on either the ‘vacuum’ or ‘pressure’ side.

NOTE: it is advantageous to install H2SPlus on the ‘vacuum side’ when possible since such a design may offer potential total system performance advantages such as protecting more system components from H2S exposure, reducing total system horsepower consumption and possibly reducing capacity requirement on other system elements.

Performance – Iron Sponge Media H2S Removal System

Predictable & Consistent Performance. Guaranteed.

MV applies the best available technology to clients’ site specific conditions in order to deliver H2S removal systems at the lowest total cost of ownership with a performance guarantee to meet target outlet concentration. H2SPlus Systems are Performance-Based.

- Operated at 100% effectiveness immediately upon startup.

- NOT susceptible to fluctuating gas conditions.

- Removes 13 lbs. of H2S per cubic foot of media.

H2SPlus Systems are guaranteed to meet target outlet concentrations, regardless of seasonal variations / fluctuations of H2S inlet ppmv. An increase in H2S concentration only affects the rate at which the media is consumed and not the performance of the system. And, at $1.31 per pound of neutralized H2S — our enhanced iron sponge media, coupled with our engineered systems, provides the most economical dry scrubber in-market. Importantly and unlike biological scrubbers, an H2SPlus Systems will absorb large fluctuations of incoming H2S concentrations, and continue to deliver the designed outlet condition without deviation. Therefore, if your project has a “bright-line limit” on H2S or SO2 concentrations, there is no need to worry about whether changes in feedstock, water conditions, or any other incoming variable will put you out of compliance when using the H2SPlus System.

B.A.M.(TM)

Additionally, it is important to point out that MV modifies commercially available iron sponge and markets it as B.A.M. (bio-active media). MV purchases standard grade iron sponge product from a commodity supplier, and enhances that material with biological agents to produce a more reactive and effective media. The iron hydroxide in the B.A.M., neutralizes the H2S by converting it into iron sulfide compounds through chemical reaction, and the bacteria serve to “refresh” the available reactant. MV’s addition of biological agents to media result in removal of numerous non-sulfur bearing species such as VOC’s and readily biodegradable organic compounds, and improved re-oxidation of the iron sulfide compounds (troilite and pyrite) to regenerate iron oxides for subsequent reactions. All of this adds up to extended life of the reactive media and lower cost of operation.

Note: MV does not sell B.A.M. for application in other dry scrubber equipment installations. The total performance that we secure from our media is in part driven by the specific engineering elements of the H2SPlus system design and it is the combination of the two that enable MV to offer its MV Performance Guarantee.

Benefits – Iron Sponge Media H2S Removal System

The MV Technologies Difference

- Flexibility & Scalability

- Consistency of Performance

- Lowest Total Cost of Operation

The key operating advantages of H2SPlus Systems are:

- Extended media life

- Minimal operator attention

- Reduced operating expense

- Dramatically increased ease of system use; and

- Infrequent, predictable, efficient and safe media change outs. Watch media changeout video*

At end of life, MV’s media:

- is non-hazardous

- passes the Environmental Protection Agency’s T.C.L.P test and meets O.S.H.A. definitions of a “not readily ignitable solid”

- can be composted, land-applied, or disposed of in landfills.

Click here to download brochures from our ‘Resources’ page.*

H2S Plus Systems

- What is the H2SPlus™ System?

The H2SPlus™ System from MV Technologies is an H2S removal system that utilizes dry scrubber technology. Dry scrubber technologies are deployed to effectively and efficiently eliminate mercaptans and H2S from a variety of gas streams. - Why Remove H2S From Gas Streams?

When H2S is produced, it releases contaminants and potentially toxic and corrosive gases into surrounding equipment and environments. - Which Gases Can be Treated With an H2S Scrubber such as the H2SPlus™ System?

H2S scrubbers can treat biogas, landfill gas, industrial gas streams, and natural gas locations. - How Does the H2SPlus© System Work?

Bio-active media are used to neutralize H2S through chemical reactions. These chemical reactions involve the utilization of iron oxide, triggering the conversion to iron sulfide and water, which helps regenerate media with oxygen over time. - What is Bioactive Media?

Bioactive media is a type of iron sponge enhanced with specific bacteria. Once the iron sponge is enriched, it becomes much more effective and reactive, extending its durability and lifespan when removing H2S from nearby gas streams or pipes. - What are the Key Elements of the H2SPlus™ System From MV Technologies?

Key components of the H2SPlus™ System include an integrated recirculation system, a blower, bio-active media, a spray nozzle, a sump, MVNets©, and a built-in control system for ongoing monitoring. This allows for consistent maintenance on-demand, preventing corrosion and unnecessary wear and tear on pipes and equipment in use. - Who Can Benefit From the H2SPlus™ System?

The H2SPlus™ System is suitable for a range of industries, including farms and agricultural organizations, wastewater treatment facilities, food processing centers, gas production operations, and even oil refineries. Any facility that utilizes gas pipes or streams is likely to benefit from H2S removal with the use of a system such as the H2SPlus™ System. - Can the H2SPlus™ System Handle Varying H2S Concentrations?

Yes, MV Technologies will work to ensure your H2SPlus™ System is designed to handle your H2S concentration and removal needs. Our systems are routinely inspected and maintained to maintain consistency and efficiency over time. - What are the Top Benefits of Removing H2S Using the H2SPlus™ System?

Using the right H2S removal system for your industrial or commercial needs is crucial. A proper H2S removal system can prevent corrosion, equipment damage, and even the release of potentially toxic gases into the surrounding environment. - What Makes the H2SPlus™ System Stand Out From Alternative H2S Scrubbers?

The H2SPlus™ System uses biologically enhanced media with modern technologies in a proven system for consistency, efficiency, and scalability. The H2SPlus™ System also offers immense flexibility and reduced operating costs while simultaneously creating safer and healthier environments. - How is the Size of an H2SPlus™ System Determined?

MV Technologies will work to determine the H2S concentration in a particular site while also observing and monitoring pressure, gas sources, flow rates, and specific outlet concentrations to determine the right system configurations for your needs. Your particular industry, facility, plant, or organizational needs will also be taken into consideration while configuring your H2SPlus™ System. - What Maintenance is Necessary for the H2SPlus™ System From MV Technologies?

In order to maintain your H2SPlus™ System, you may require periodic inspections and media replacement. Ongoing monitoring of your H2SPlus™ System’s performance is also advisable to ensure the proper functioning of integrated blower systems, ventilation configurations, and recirculation.