H2S Removal Systems

MV Technologies hydrogen sulfide removal systems are used to treat biogas for emissions control for beneficial end-use across all biogas processes on farms, at wastewater treatment facilities, and for large waste and industrial facilities. If your facility is in need of such services, you know how important it is to have responsive, effective, and durable systems in place.

H2SPlus™ Systems and SulfAx™ Systems

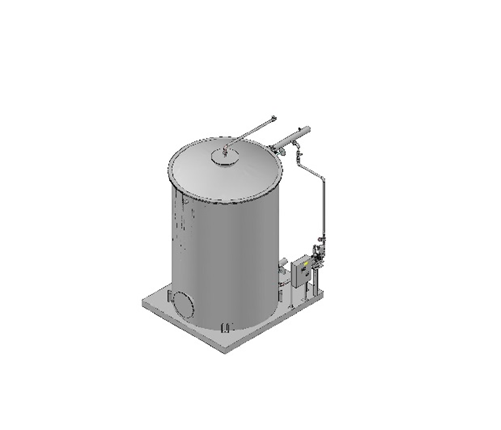

MV Technologies offers two types of H2S removal systems: H2SPlus™ Systems and SulfAx™ Systems. These systems are designed to handle variations in feedstock source, temperature changes, and fluctuations in water chemistry, which can significantly impact H2S concentrations in the biogas stream.

H2SPlusTM Systems

Designed to optimize iron sponge media for the purpose of removing H2S from LFG, biogas and natural gas streams. H2SPlusTM Systems

combined with B.A.M.TM enhanced iron sponge media and the use of MVNetsTM offer consistent, reliable performance and safer media removal at the lowest cost per pound of H2S removed.

SulfAxTM Systems

Designed to optimize high capacity granular media for the purpose of removing H2S from LFG, biogas and natural gas streams. SulfAxTM Systems

combined with high-capacity granular media offer the ability to meet stringent H2S outlet concentrations with even greater ease of media removal than other systems.

Tailored Solutions for Various Industries

We successfully partner with engineering firms, design & build companies, and end-users to help identify and design the right H2S removal solution for site-specific requirements from the common mixed reactor to dry anaerobic digestion to plug flow anaerobic digestion processes. Our team provides unique solutions that meet your exact needs. These tailor-made systems ensure that your H2S removal process is appropriate for your facility.

MV Technologies’ H2S removal solutions offer design flexibility and are often the most cost-effective and easy-to-operate technology for most AD biogas projects. No matter the size of your organization, we can help you from design to implementation and every step in between. We’re the team to call if you’re looking for a partner to help you with effective and efficient H2S removal solutions.

The production of H2S during anaerobic digestion is a complex biological and chemical process that is highly variable across various applications, even within a single digester. This is why it’s so important to work with a company that understands the ins and outs of these processes and knows how to create an effective and unique removal system for you.

Variations in feedstock source and consistency, temperature changes, and fluctuations in water chemistry can significantly impact the quantity of H2S included in the biogas stream. These variations in H2S concentrations can present significant challenges to conventional biological systems.

Navigating H2S Concentration Variability

H2S concentrations in biogas from anaerobic digesters can range from highs of more than 20,000 ppmv to values of less than 100 ppmv, and, as noted above, the fluctuations around a mean value in any given digester can be significant. The variability in concentration is one of the peculiar and critical elements to address in the design of an H2S removal system.

Additionally, in evaluating H2S treatment approaches, an important metric to consider is the Total Cost of Ownership (TCO).

The TCO includes capital costs such as the vessel size, pumps and installation costs, and the operating costs, largely determined by media life and resulting time between replacement — itself a function of biogas flow rate and H2S concentration. MV’s enhanced iron sponge (BAM) media is guaranteed to remove up to 13 pounds of H2S per cubic foot, one of the highest removal efficiencies in the industry.

Click here to calculate cost based on annual pounds of H2S removed for your project

Cost elements that are often overlooked during comparison of H2S treatment approaches:

- Power costs – an increase in pressure drop can result in increases in power costs

- Lost Revenue due to system downtime – maintenance/media changes

- Replacement of proprietary nutrients and/or chemical/caustic

- The costs of testing for warranty or regulatory requirements

- Operator attention time – it is not “free”

Contact us today to learn more about our comprehensive H2S removal solutions and how our team can help you create a system to meet your needs today and in the future.

Frequently Asked Questions

Eliminating excess buildup of hydrogen sulfide, or H2S is imperative whether you’re working in a commercial warehouse, waste facility, or if you’re managing a chemical production company. As organic materials begin to decompose or trigger anaerobic digestion, H2S is produced as a result of various chemical and biological processes that are naturally occurring in nature. When toxic gasses (such as H2S) are released unfettered into the surrounding atmosphere, they can contribute to health, safety, and environmental risks.

Regulatory compliance is imperative when managing chemical plants, wastewater treatment facilities, or other high-risk commercial locations, indoors and out. Compliance with local environmental regulations will prevent unnecessary fees and fines while providing a safe and healthy work environment for employees. Successfully eliminating H2S from the atmosphere will also significantly reduce the risk of exposure to noxious gasses, which can result in adverse health effects.

Selecting the right H2S removal unit or system is vital, whether you’re overseeing the operations of a traditional wastewater treatment plant or you’re working with VOCs or volatile organic compounds regularly each day at your facility.

Currently, MV Technologies provides two advanced H2S removal systems for clients — H2SPlus© Systems and SulfAx© Systems. MV Technologies can help assess the TCO (Total Cost of Ownership) and H2S concentration variability to pinpoint your facility’s exact needs and demands for seamless H2S removal.

H2SPlus© Systems are ideal for removing landfill gas, natural gas streams, and even biogas from surrounding environments with the use of B.A.M. iron sponge media.

Safer: MV Technologies utilizes its own MVNets© solution to remove H2S with little to no risk with the H2SPlus© Systems in place.

Cost: If you’re interested in saving on costs, you can do so with the use of a B.A.M. iron sponge and the right H2SPlus© Systems solution.

Extended Lifespan: Activated agents found in B.A.M. make it much easier to increase the efficiency and overall lifespan of the iron sponge itself.

Lack of Versatile Applications: Unfortunately, the H2SPlus© Systems are a bit more limited in terms of environmental requirements for complete optimization of the system itself.

For those who are searching for high-capacity granular media to remove H2S from surrounding environments, SulfAx© systems may be right for you. The use of high-capacity granular media makes it easy to eliminate H2S from larger locations, including natural gas streams, waste treatment centers, and even biogas plants.

High Capacity Solution: Using high-capacity granular media is ideal for environments with higher-than-average concentrations of H2S in the atmosphere.

Easy Cleanup and Removal: Easily remove and replace SulfAx© Systems to save time and optimize operations.

Regulation Approved: SulfAx© Systems are ideal for those interested in abiding by stringent regulations and environmental requirements.

Costs: Initial investment in a SulfAx© System is likely to be much higher than a traditional iron sponge alternative.

Disposal: The handling and disposal of granular material must also be considered when considering the use of a SulfAx© System for your H2S gas removal.